As humans work towards powering their tools in cleaner ways, electricity becomes more and more important. Solar design Engineer Douglas Bolstridge and the people he works with create systems which help families and businesses use the sun to create electricity to meet their needs.

What do you use electricity for?

(Try to tell your class about something you use it for that has not already been mentioned.)

In the first half of the year 2024, most of the energy added to the United States’s power infrastructure was solar. The EIA (US Department of Energy Information Administration) reported that of 20.2 GWac in power plants added to our electric grid, 12 GW or 59% came from solar. (One GW or gigawatt is a billon watts: 1,000,000,000 watts. “Ac” refers to alternating current – electrical current which can change directions.) Many of the new solar projects were in the states of Florida and Texas.

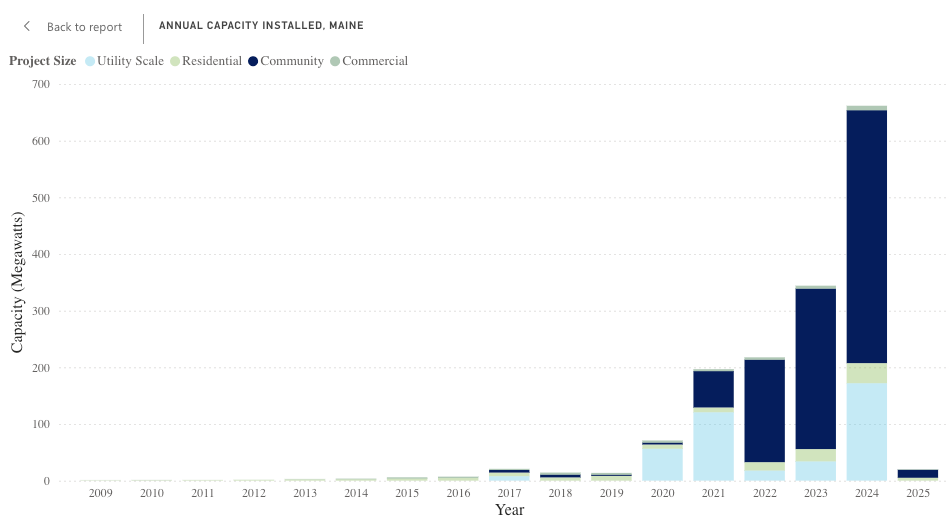

Unlike Florida and Texas, the state of Maine is not widely known for being a sunshine state. Located in the northern U.S., Maine has long winters with short days. But according to the EIA, renewable resources powered more than half (67%) of Maine’s electricity generation in 2023. And by January, 2025, 1,562 MWac was generated in Maine. What is a MW? A megawatt (a million watts) can power your home for a full year or help an electric car drive 3,600 miles.

More and more solar projects have been taken on in Maine, as you can see from this graph at its governor’s energy website.

There’s a need for clean, renewable sources of power as carbon and other greenhouse gases in Earth’s atmosphere heat the planet. This need and the growth of the solar energy industry create interesting jobs for engineers like Douglas Bolstridge. As a solar design and interconnection engineer who also works as a project manager, all for Sundog Solar, a company in Searsport, Maine, Bolstridge helps people and companies in his state capture and use energy from the Sun.

A large project Bolstridge helped with involved putting about 350 solar panels on an apartment building in Bartlett Woods Retirement Community, in Rockland, Maine. The goal was to supply half of the community’s electricity. According to the website Mainebiz, the panels should prevent 230,000 pounds of carbon dioxide from going into the atmosphere each year.

I [Bolstridge] was there from day one, taking photos and doing a site visit. I then worked up on the roof of the building doing layouts and seeing where the equipment would fit. I also worked on all of the designs and interconnection paperwork and when the project was done, CMP [a power company in Maine] had us install a new service pedestal, and I did that as well.

The largest project that Bolstridge has been part of at Sundog is one in Veazie, Maine, where the company was subcontracted to help build a 2.7 MW (megawatt) utility-sized solar field. The idea was to generate enough energy to power hundreds of homes, perhaps as many as 500.

One limit Bolstridge and his colleagues can face comes from large energy companies. The people who run them want to maximize their profits, which they still make most easily by supplying homes and businesses with fossil fuel – based energy. As of 2024 natural gas was still the largest single source of electricity in Maine.

The infrastructure power companies rely on is often old and cannot connect with unlimited renewable energy sources like solar fields and solar panels on individual homes and businesses. Bolstridge himself has been told that he cannot put a solar system on his house in Winterport.

But Maine intends to produce all of its energy from renewable resources by the year 2050. One way to get this done is to rebuild and expand the energy infrastructure, allowing Bolstridge and other engineers to use their interconnection skills to connect homes and businesses to power companies’ grid. Another is to go off grid, storing solar energy produced around the state in local batteries rather than connecting it to the existing power companies.

Of course, the batteries needed to go off grid can be pricy. Bolstridge told Math4Science that an off-grid system can cost as much as $50,000. “Compared to a utility system, that’s too expensive for most people.” On the other hand, once an off-grid system is installed, there are no monthly electric bills. The only costs after installation involve replacing components if they fail, but most are under warranty for as much as 20 years.

And individual batteries may not store enough kilowatts to power the home or business where they’re installed. At this point, Bolstridge says that a 13.5 kilowatt hour (kwh) battery can only meet a whole home’s electrical needs for about an hour. That won’t do much for people in a state where some storms lead to 10-day power outages, like the one Bolstridge faced in 2024. He had to drive to his in-laws’ home and stay there while the power was out at his place.

Douglas grew up in Smithfield Maine, on a lake. He spent time in the woods with his father, bear-baiting. Perhaps that’s part of what inspired him to go to Unity College to study biology. From there, he tried Maine Maritime Academy, where his stepfather encouraged him to go. But in order to help his family out during a health crisis, Bolstridge left school to go to work.

Eventually, his partner Brynn and his own desire to finish the education he had started and become the first in his family to graduate from college led Bolstridge to apply to the University of Maine’s MET (Mechanical Engineering Technology) program. “I’m a hard worker and I like to do things with my hands.” Facing debt from the other schools he had attended, Bolstridge realized that getting a “big-boy job” would be easier if he finished college.

It had been a few years since Bolstridge had sat in classes, studied, and done the math necessary to get an engineering degree. He found that working with his classmates – “learning from each other is always good” – helped him succeed. And he enjoyed the labs. He had learned to use a lathe and how to weld in high school and at Maine Maritime.

His capstone project at the MET program involved designing, manufacturing, and riding a 3D-printed bicycle. Bolstridge rode bikes a lot but had never built one or used a 3D printer. Now he had to think about the different forces at work as you ride a bike and how they would affect its different parts. He used “lots of math and geometry, bringing all the math you learned at school and applying it at a higher level.” The whole process was “really fun” – Bolstridge “put in 580 hours of seat time” at his computer, more time than any of his team mates spent on the project. He also spent hundreds of hours riding and testing the bicycle and reprinting parts to improve them. The bike frame and rear forks – everything but its handlebars, chain, and front forks and wheels – was 3D-printed.

After graduating from the University of Maine, Bolstridge worked for Nile Systems, a company which built “essentially a heat pump before heat pumps were a thing.” They dehydrated food, lumber, and other products. Bolstridge was able to use his 3D-modeling skills to help design custom dehydrators. He got to make “everything we couldn’t buy,” creating parts and also designs for them so that others could also make them. One project was for a Boston company which dehydrated fish (pollock and cod skin) for dog treats.

Creating systems and tools for those systems requires what school teachers might call “showing your work.” Young math students sometimes write down answers to the problems they solve and feel frustrated when they don’t get full credit because they didn’t show how they found those answers. Engineers like Bolstridge have to show their work! Why? “So that other people can learn how you’re doing it and also so that you have a better understanding of how you’re doing it.”

When he left Nile, Bolstridge moved to Sun Dog, where he enjoyed the work environment and the opportunity to design renewable energy systems. When he had been at Maine Maritime, he participated in a 70-day cruise to a geothermal power plant in Iceland. The plant pulled warm water out of the ground and also cold water. Its system created steam power with less energy than other systems require. A boiler makes the steam, which turns a steam turbine to produce electricity. This “intrigued my interest.”

At Sun Dog, Bolstridge finds himself doing “lots of different types of math.” He works to match the energy a household or business uses to the size of the solar system he designs. This involves checking their kilowatt usage over a year and choosing an inverter that will help them produce the same amount of energy. Then he has to “string series of panels together,” each one allowing an input of up to 600 volts, to harness enough of the sun’s energy to meet that household’s (or business’s) needs. This all involves “a lot of basic adding, multiplying, and dividing.”

And he uses Ohm’s law and Ohm’s triangle to convert between volts, amperes, and kilowatt hour measurements of power, current, and voltage. For instance, he might divide 10,000 watts by 240 volts to find the amperage (how much? Find that number.). That helps him size the wire he needs.

What math does Bolstridge wish he had learned better? “I wish I would have known the multiplication tables better – by heart – and not have had to use a calculator all the time.” He learns from his colleagues and from the things he reads as well as videos he watches “but the quick math in my head I wish I could do better.” In school, he didn’t learn the times tables but now he finds that he is good at memorizing things.

The work of setting up safe systems is fun. “I really like sizing systems and seeing that it’s going to work out,” says Bolstridge. His solar systems help move Maine towards meeting its renewable energy goals and a day that families like Bolstridge’s meet their power needs without heating Earth’s atmosphere as much.